Features

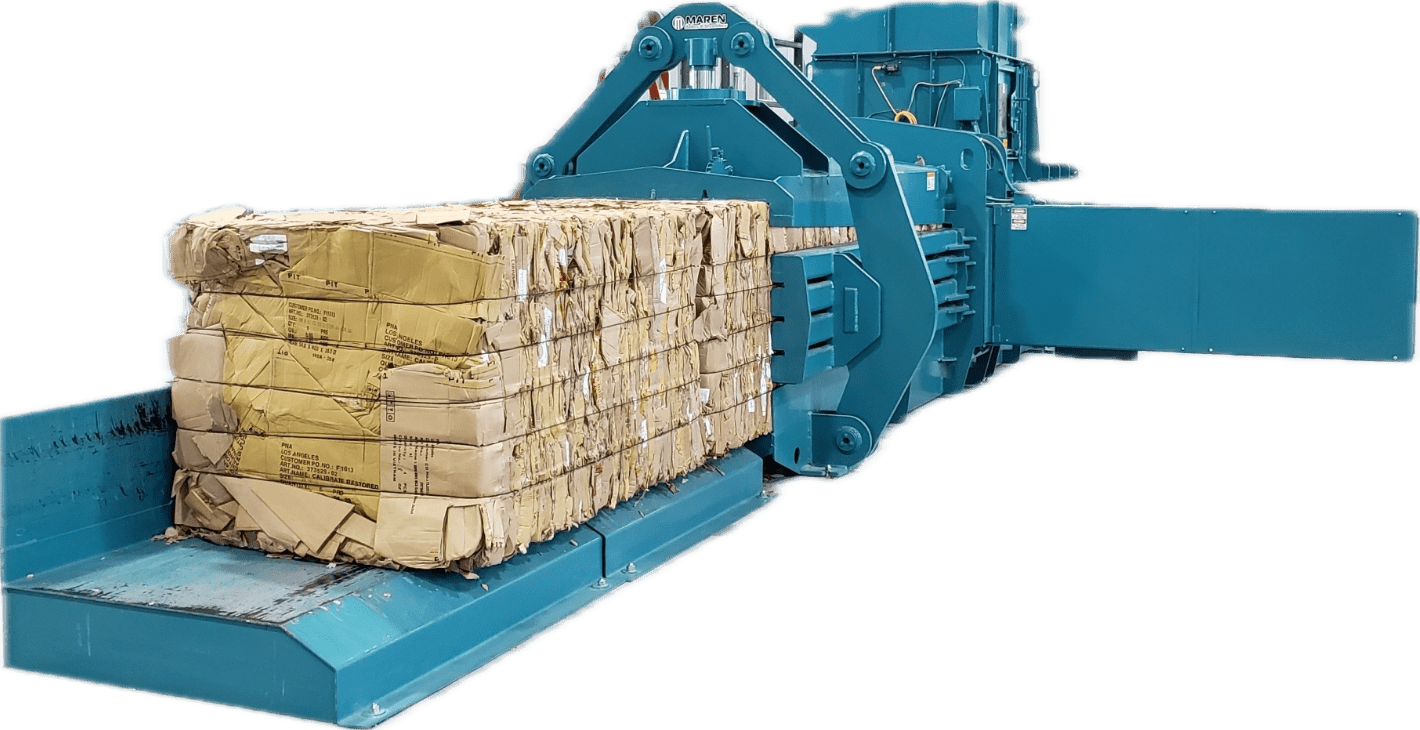

The Maren ProPAK A160W baler & Maren ProPAK 210W baler are engineered for demanding waste management environments. With their auto-tie system, durable steel construction, and precision design, these heavy-duty balers are ideal for anyone seeking waste equipment that offers reliable, high-capacity performance. Take a look at the features that make the A160W and 210W industrial balers truly standout solutions.

- Single-cylinder “A” frame compression chamber delivers full-force compaction by aligning ram pressure precisely during the high-pressure phase of each bale cycle.

- Produces bales measuring 45″ wide with variable lengths, achieving weights up to 2,500 pounds depending on bale density and moisture.

- Optional bale lengths of 45″, 64″, and 80″ to accommodate various material handling and storage needs.

- Customizable hopper options ensure compatibility with a variety of infeed systems, including shredders, conveyor belts, air conveyance, and cart tippers.

- Fully automatic 5-wire tying system uses an electric wire loader for consistent, hands-free bale securing.

- Optional high-capacity wire handling features include stump wire carriers (1,000 to 1,500 lbs) and a powered hoist for safe, efficient wire reloading.

- Progressive shear blade design penetrates up to 30 inches into the load, minimizing material hang-ups and maximizing ram pressure during compaction. Blades are double-edged, replaceable, and made from precision-ground hardened tool steel.

- Durable interlocking chassis construction spreads mechanical stress across the steel plates themselves, reducing strain on weld seams and enhancing long-term structural integrity.

- AR400 wear liners reinforce the high-strength steel plate floor, offering exceptional durability and extended service life with minimal maintenance.

- Sealed ram system uses NylOil wear guides on the sides and bottom and an AR400 spring-loaded scraper at the top to prevent debris intrusion and material migration.

- Front and rear chassis access door provides direct entry to key service areas. The door is electronically interlocked for safety and may be padlocked to restrict access to authorized personnel.

- Proprietary cylinder mount design offloads stress from the bolts using a key-lock mechanism, improving durability while simplifying maintenance and service access.

Applications for the ProPAK Wide Auto-Tie Baler

The Maren ProPAK A160W & Maren ProPAK 210W are purpose-built for industries that generate high volumes of waste, providing an efficient baling solution for busy environments. Their reliable engineering makes them a go-to choice for businesses needing an integrated recycling baler that complements automated workflows. If you need a dependable paper baler, plastic baler, or cardboard baler, these waste management solutions will get the job done.

- High-Throughput Facilities

Built for continuous bailing operations, the A160W & 210W are durable machines that support fast-paced workflows and integrate easily into automated recycling systems to keep production moving. - Logistics Centers

From packaging remnants to plastic wrap, these compact balers help fast-paced environments manage waste quickly and efficiently. Their auto wire tier simplifies waste compaction processes and supports sustainability goals. - Industrial Plants

Manufacturing operations in need of a warehouse baler can rely on these machines’ robust build system to maintain uninterrupted productivity and reduce manual labor requirements. - Operations Requiring Reliable Uptime

This recycling automation system is built for frequent use. The rugged construction, simplified service access, and jam-resistant horizontal shear baler design make it one of the most reliable options for long shifts and multi-shift operations.

ProPAK A160W & 210W high-output balers combine intelligent engineering with reliable performance to meet the demands of modern waste management environments.

Reviews

There are no reviews yet.