Features

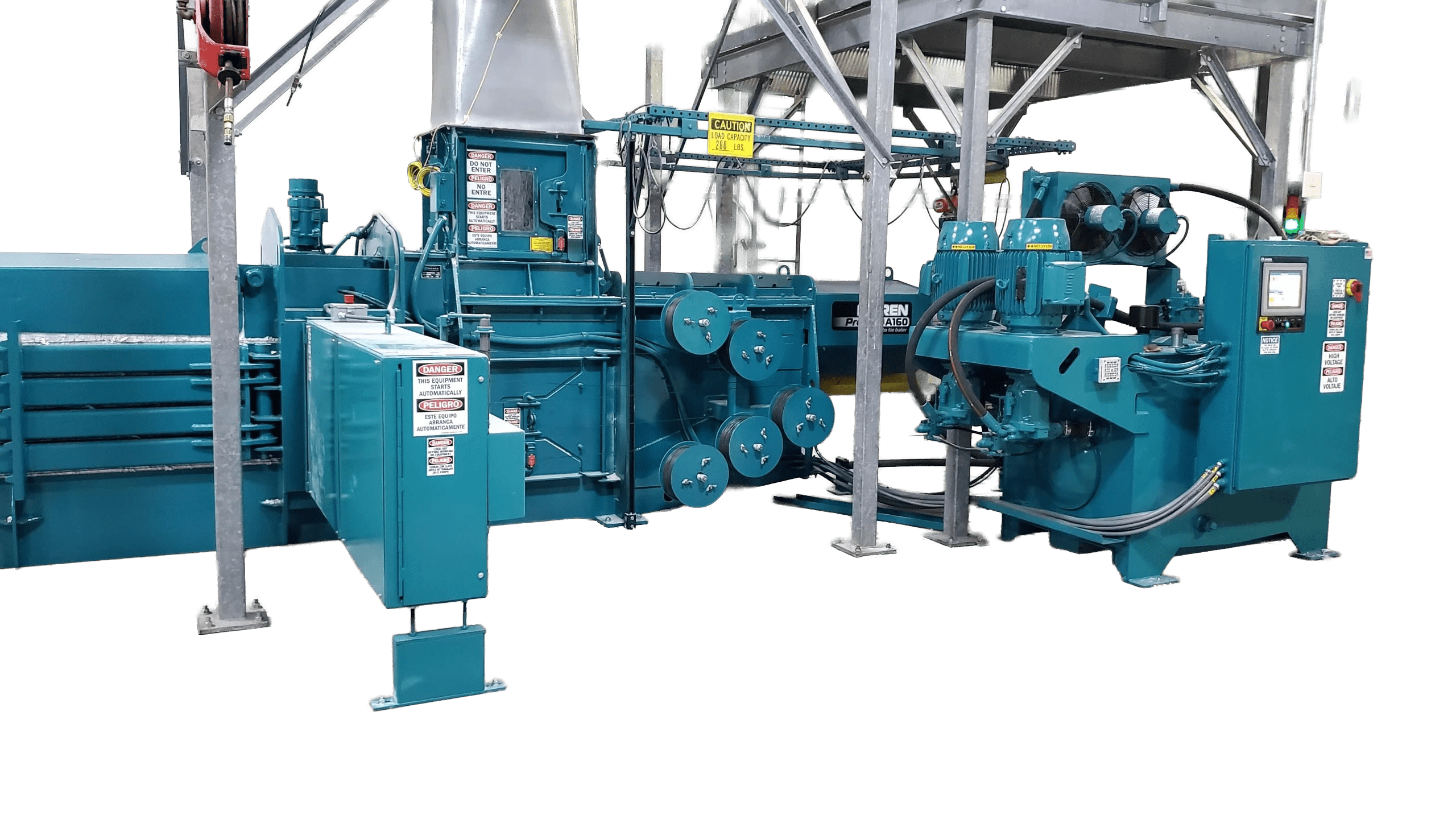

The Maren ProPAK A160 trim baler raises the bar for performance and reliability in the printing, corrugated box, folding carton, and paper converting sectors. Known for their quality and resilience, Maren balers have long been the equipment of choice in these kinds of trim-intensive industries. The A160 continues that legacy with an even more durable build and upgraded capabilities specially designed for the rigors of continuous trim processing.

- “A” frame single-cylinder tension chamber maximizes compression during full-pressure baling

- Produces bale sizes of 30″ x 40″ x variable length, with weights up to 1,750 lbs

- Adaptable hopper sizes to integrate with air conveying, shredders, or trim capture systems

- Advanced 5-wire auto-tie system with electric inserter and twister

- Optional 1,000 lb. bulk wire feed carrier and electric hoist for easier wire reloading

- 30″ progressive shear blade penetration to reduce jams and maximize force application; Maren double-edge blade is made of hardened steel

- Interlocking steel construction significantly strengthens the chassis and weld joints

- Replaceable AR400 wear plate on the baler floor ensures exceptional durability

- Sealed ram design with NylOil guides and spring-loaded scraper to prevent material bypass

- Electronically interlocked, lockable service doors for maintenance access; can also be padlocked for extra security

- Maren’s exclusive key-lock cylinder mount for easier servicing and greater mount longevity

Applications for the Maren ProPAK A160 Trim Baler

The Maren ProPAK A160 trim waste baler is engineered for versatility and built to meet the needs of space-conscious operations handling high volumes of continuous trim. Its integration-ready design and small footprint make it a go-to low-maintenance baler for many production environments. Its ideal applications include:

- Printing Operations

A trusted trim baler for managing print shop waste such as newsprint edges, glossy trimmings, and overruns. Produces high-density bales to streamline hauling and reduce manual material handling. - Packaging Facilities

Tailored for the needs of a packaging facility, the A160 collects and compacts trim from carton and corrugated processes, offering a true compact waste compactor solution with automatic tying and jam-free operation. - Paper Recycling Plants

Designed to handle lightweight yet bulky waste types like envelope cutoffs and coated paper, this efficient baling solution integrates into any automated recycling system. - Envelope & Carton Manufacturers

A heavy-duty trim baler that handles high-speed converting lines with ease, this model automates waste capture and ties bales consistently, which helps facilities maintain uninterrupted output. - Facilities with Tight Layouts

Thanks to its compact baler design and small footprint, the A160 fits into tight production environments without compromising throughput or serviceability. - High-Output Industrial Plants

As a rugged industrial baler, the A160 is ideal for plants that require reliable waste management across multiple shifts. It forms the heart of a durable baler system that operates with minimal downtime while delivering consistent bale density.

The Maren ProPAK A160 is a durable, automated, and user-friendly baler for trim applications, capable of transforming complex waste streams into clean, manageable, and transport-ready output.

Reviews

There are no reviews yet.