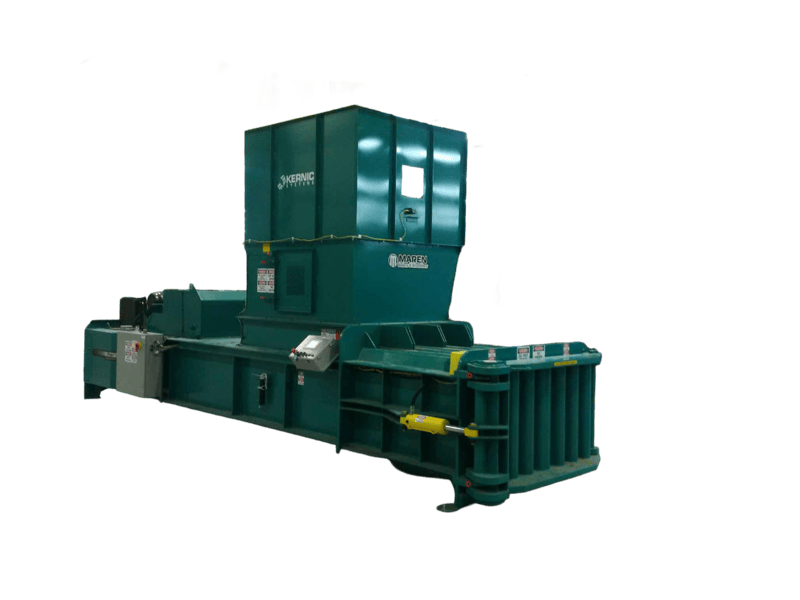

ProPAK 60 Features

- Largest feed opening in its class (54″ x 40″)

Flexible hopper easily handles full-size, unbroken boxes without jamming—ideal for use with a baler for conveyor systems, shredders, or direct loading. - Superior compaction force of 109 PSI

Provides 20% more platen pressure than most competing manual tie balers, delivering higher bale densities and improved shearing performance across various waste types. - AR400 abrasion-resistant floor liner

A durable, replaceable wear part that extends baler floor life and reduces maintenance in demanding waste baling machine - SmartBale™ intelligent controls

Automatically adjusts bale sizes, compression settings, wire locations, and sensor functions for different materials—optimizing loads for trucks and sea containers. - Advanced shear blade design

A 27-point chassis shear and progressive platen shear system minimize clogging, enabling consistent operation in high-volume recyclables processing. - Streamlined manual tie wire system

Engineered for speed and simplicity, the easy-tie design eliminates debris interference common in other manual tie systems and outperforms many auto-tie alternatives. - Heavy-duty material retention dogs

Prevent compressed material from springing back into the feed chamber, maintaining continuous flow and waste reduction - Built-in bale decompression cycle

Automatically retracts the ram before the bale door opens, enhancing operator safety during bale ejection. - High-efficiency hydraulic system with piston pump

Delivers class-leading compaction force while reducing energy consumption, leaks, and complexity—ideal for industrial settings seeking performance with fewer components. - Interlocked steel frame construction

The steel construction frame and ram use an interlocking design to better absorb structural stress and provide long-lasting weld durability. - Reinforced bale door and oversized cylinder mounts

Modeled after non-ferrous balers, the full eject baler door system and heavy-duty mounts enhance longevity and resistance to high loads. - Operator-friendly control panel with optional remote

Centralized baler controls are positioned within clear sight of the door latch, with remote operation available for customized commercial baler

ProPAK 60S Features

- Class-leading 54″ x 70″ feed opening

The largest in its category, this ProPAK 60 stretch model accommodates oversized materials like slip sheets, foam, and large boxes—ideal for commercial recycling of non-standard items. - 104 PSI platen pressure for maximum material compaction

Delivers significantly higher force than many comparable manual tie balers, improving throughput for waste types like plastic film, flexible packaging, and polyurethane foam. - AR400 floor liner for rugged longevity

Built with a replaceable wear part in high-contact zones, this baling press resists abrasion and extends service intervals under intense processing conditions. - SmartBale™ automatic setup

Simplifies operation by tailoring bale sizes, wire placement, sensor settings, and compression profiles for each material, making it a user-friendly waste management - Optimized shear blade geometry

The integrated 27-point chassis shear and platen shear use chamber-specific shaping to prevent clogging and ensure reliable function—hallmarks of Maren’s advanced replaceable wear parts. - Enhanced manual tie wire system

Designed for speed and accessibility, this tie-off channel supports clean wire feed paths and reduces the learning curve compared to traditional or assisted tie mechanisms. - Retaining dogs for high-rebound materials

Prevents compressed foam, plastic, and other resilient material from rebounding into the chamber—critical for efficient recyclables processing. - Built-in bale decompression safety feature

Automatically retracts the ram after bale completion, preventing accidental pressure discharge when accessing the chamber—an essential for any baler with service door. - Hydraulics engineered for low energy loss

The streamlined hydraulic system offers better efficiency than some 30 HP models, using fewer hoses and components to reduce maintenance points. - Interlocked steel frame and ram assembly

This steel construction baler uses interlocking fabrication to absorb stress and deliver greater structural integrity than welds alone. - Extra-durable door and cylinder mounts

These reinforcements are ideal for waste compactor systems processing bulky, awkward loads. - Operator-friendly electrical controls

The baler controls are centrally located for visibility and ease of use, with optional remote stations available.

Applications for the ProPAK 60 & 60S Balers

The Maren ProPAK 60 and ProPAK 60 stretch (60S) models are engineered to meet the diverse needs of industries requiring reliable, high-output manual tie balers. Designed to process a broad range of recyclable materials, these machines are built for operations that emphasize waste volume reduction, durability, and bale consistency—making them excellent choices for both centralized and on-site baling.

Common Applications Include:

- Manufacturing Plants

Ideal for facilities producing consistent streams of paper trim, plastic offcuts, and light metals. These industrial balers offer exceptional throughput for layered packaging and production byproducts, as they’re capable of managing even heavy bale weights. - Warehouses and Fulfillment Centers

The large feed openings and easy wire tie system make these units perfect for handling broken pallets, corrugated void fill, and return packaging—transforming clutter into manageable, compacted bales. - Commercial Printing Facilities

As a dependable paper baler, the ProPAK 60 series handles continuous sheets, press trimmings, and bulk paper stock with ease, producing uniform, high-density bales that streamline pickup and resale. - Distribution Hubs

Designed for rugged environments, these machines are quality industrial balers for high-throughput facilities managing shrink wrap, linerboard, and excess box stock in real time. - Recycling Centers

These recycling balers offer a versatile solution for processing cardboard, newsprint, aluminum cans, and plastics. The manual tie capabilities give operators more control over output, whether these machines are used as cardboard balers or for processing other materials. - Retail Chains and Big Box Stores

Perfect for in-store waste compactor use in loading docks or back rooms, where space is tight but demand for waste reduction remains high. - Shredding and Document Destruction Services

The units pair well as a baler for shredders, converting sensitive materials into compact, secure bales for compliant handling.

Whether integrated into a larger recycling system or used as a standalone mid-sized facility baler, the ProPAK 60 and 60S deliver performance, flexibility, and long-term value.

Reviews

There are no reviews yet.