CALL NOW FOR A FREE QUOTE 866.760.8194

Your Guide to Commercial Recycling Balers

A recycling baler helps businesses control waste volume and material handling. With a baler machine, you can convert common recyclables into a format that simplifies storage and improves process efficiency. In this guide, we’ll explain how it works and how to find the right one for your commercial waste handling operations.

What Is a Baler Machine?

A baler machine is designed to compress recyclable materials into dense, manageable bales for easier handling, storage, and transport.

Waste such as cardboard, paper, plastic film, etc., is loaded into the chamber of the baler. A hydraulic ram then presses the material down (or sideways, depending on the machine style). After compaction, the bale is tied or strapped and ejected for collection or shipment.

This process has the following benefits:

- Reduces the volume of waste

- Lowers hauling costs

- Streamlines recycling logistics

- Helps organizations meet sustainability targets

- Conserves space and reduces labor

Common Types of Commercial Recycling Balers

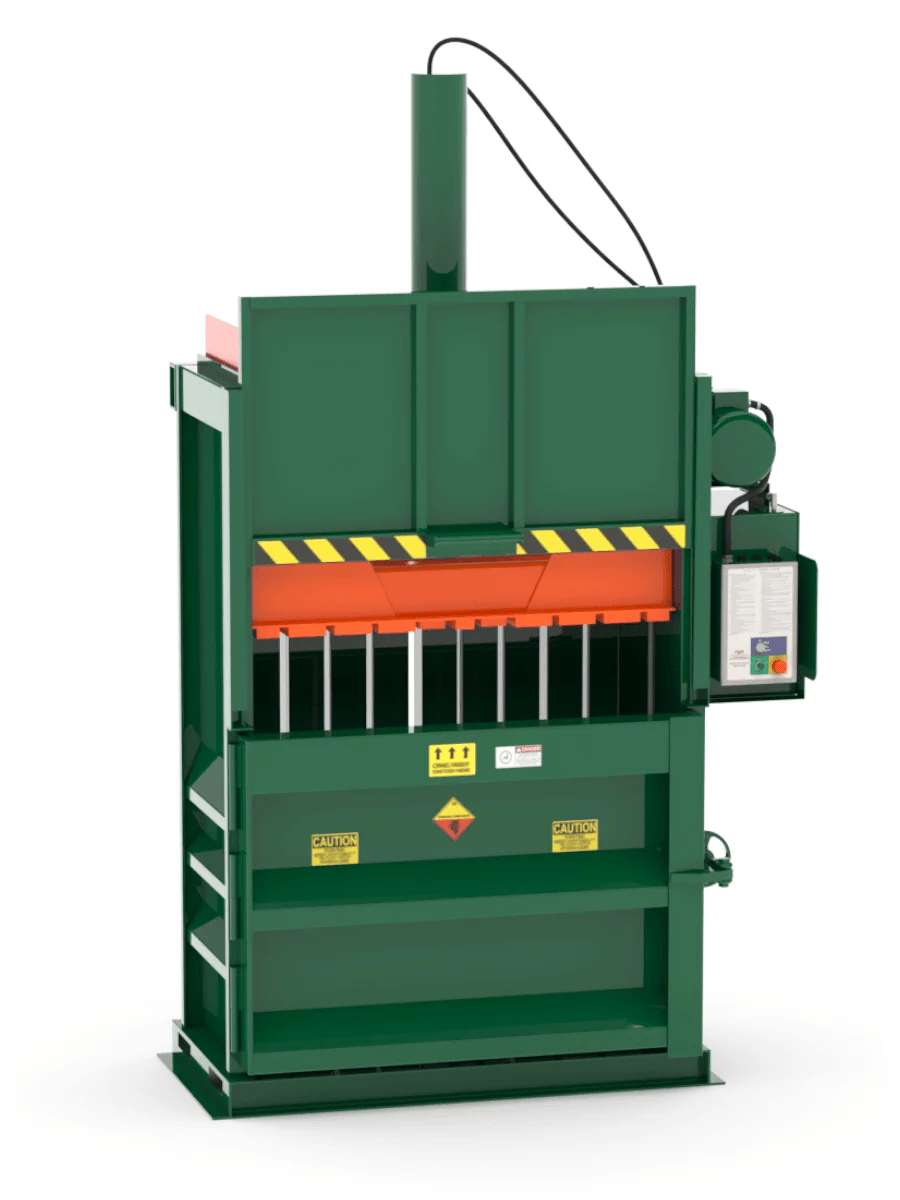

Vertical

A vertical recycling baler compresses material in a downward direction. The loading chamber is accessed from the front/top, and after compaction, the bale is tied (manually or semi‐automatically) and ejected. These machines are space‐efficient and suited for moderate volumes of recyclable waste.

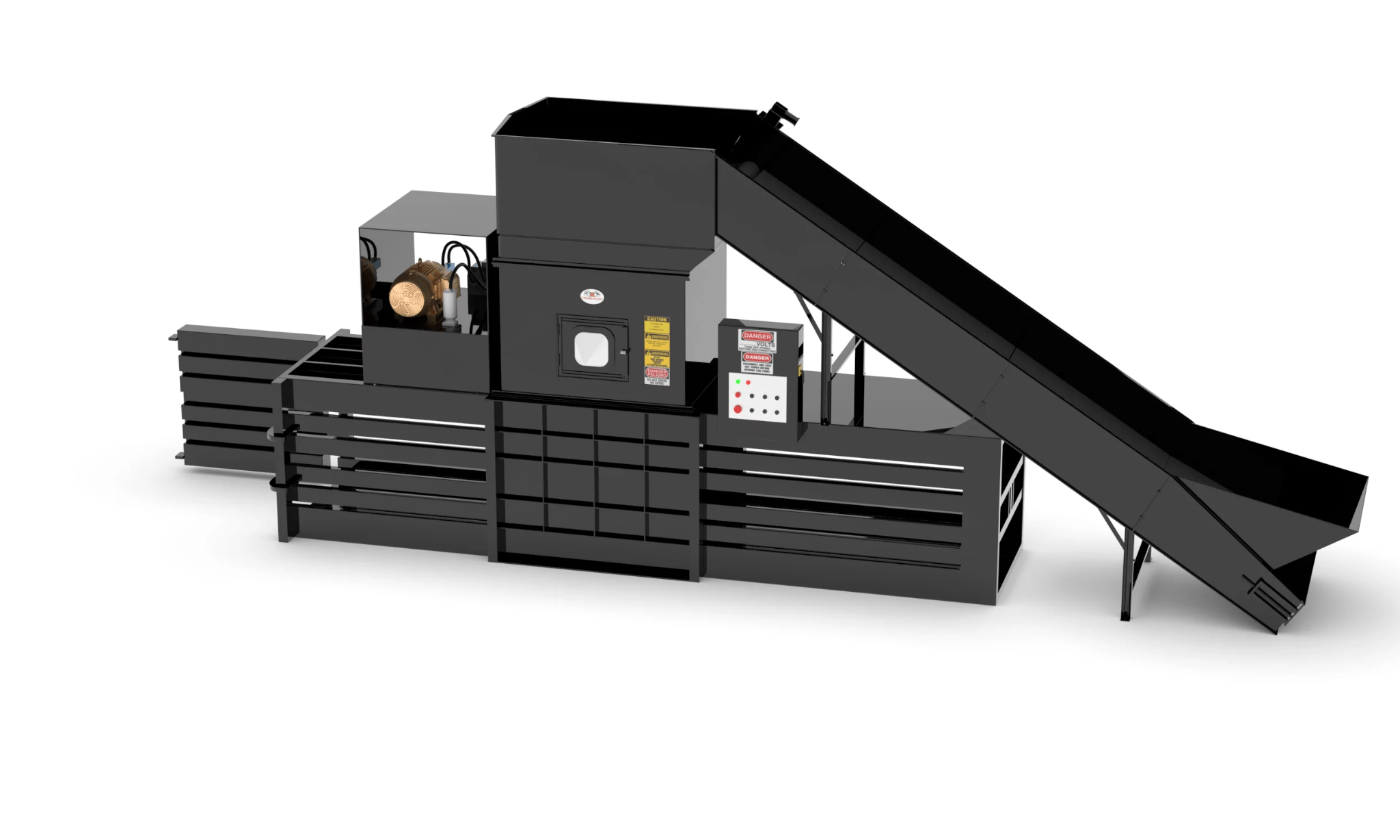

Horizontal

Horizontal balers compress material sideways or from the front, and often have a longer chamber. They are built for businesses that handle large volumes of recyclables. Many include automatic feeding mechanisms, conveyors, and continuous operation, while closed-end, auto-tie, and wide-mouth configurations are available.

When you’re comparing vertical vs. horizontal balers, you’ll find that horizontal units require more floor space and a higher upfront investment, but they can deliver greater output and efficiency for high-volume operations.

What Can Be Put in a Commercial Baler?

When it comes to what you recycle, balers can handle a variety of materials in commercial settings:

- Corrugated cardboard and shipping boxes

- Paper and newsprint

- Plastics such as high-density polyethylene (HDPE) and polyethylene terephthalate (PET) containers or shrink wrap film

- Non-ferrous metals in some balers (for example, aluminum cans)

- Textiles, fabrics, and linens in certain applications

It’s important to note that some materials should not be baled together (to avoid contamination). Certain items (for example, ferrous metals, aerosol cans, or glass) may not be suitable for standard balers without special configuration or equipment. Depending on the type and volume of materials, an upgrade to an industrial baler may be necessary.

Be sure to check with your equipment provider for compatibility based on your waste streams and material sorting strategy.

Signs Your Business Is Ready for a Baler

Here are some typical indicators that it may be time to invest in a commercial recycling baler:

- Your business generates a consistent volume of recyclable material that occupies space or requires frequent pick-ups.

- You spend significant amounts on hauling, waste removal, or compactor services and are looking for cost savings.

- Loose waste material is taking up valuable operational or storage space and interfering with workflow or safety.

- Your recycling goals demand improvements in diversion rates, recyclables management, and other efforts to generate revenue from bale sales.

- You have or can allocate space and infrastructure (e.g., loading access, power supply) for a baler machine and operator training.

When the frequency of waste pick-ups is high or the volume of recyclables grows, the ROI for a baler becomes more compelling.

How to Choose the Right Commercial Baler

Selecting the right baler machine involves aligning your operational needs with system capabilities. These are some of the considerations that are important in making an informed decision:

- Waste Volume: Look at the amount of cardboard, plastic film, or mixed paper your business produces during a typical shift. Consistent volume helps determine the size and capacity of the baler you need and prevents bottlenecks during busy periods.

- Material Type: Identify the dominant materials in your recycling stream because different balers handle specific materials with varying efficiency. This ensures the finished bales meet recycling standards and support smooth downstream processing.

- Available Space: Evaluate storage areas, workflow paths, and clearance requirements. A proper layout enables more effective baled recycling and keeps loading and bale removal efficient.

- Labor and Workflow: Consider how often employees handle recyclables and how much time they spend operating the baler. Some operations benefit from a simple load-and-press routine while others demand equipment suited for a continuous workflow.

- Budget Planning: Factor in upfront cost, maintenance expectations, and long-term savings from lower hauling frequency. A clear budget review helps you select equipment that fits both current needs and future growth.

- Operational Goals: Determine if your priority is reducing clutter, improving safety, meeting sustainability targets, or generating revenue from bale sales. These goals influence the baler size, features, and load capacity that best support your strategy.

By considering these factors and getting an expert assessment, you’ll be in a strong position to select a model that’s suited for your business.

What Our Commercial Baler Machines Recycle

The dominant material type is an important factor in making your decision. At Global Trash Solutions, we have the following waste baler solutions to choose from:

- Cardboard Balers: We offer compact vertical units for moderate cardboard volume and larger industrial systems for steady, high-output operations. These machines reduce bulky corrugated materials by up to 90%.

- Plastic Balers: We supply balers suited for films, bags, and rigid containers. They create dense, mill-ready bales and help manage various plastic types with cleaner sorting and lower hauling costs.

- Textile Balers: We provide balers designed for clothing, linens, carpets, and similar materials. These units produce uniform bales that streamline storage and movement for textile recovery programs.

Find the Right Recycling Baler From Global Trash Solutions

If your business is ready to move to the next level of recycling, partner with Global Trash Solutions. We offer a wide range of baler machines for commercial use. Financing is available to fit your budget. Reach out today at 866-760-8194 to discuss improving your waste handling, get expert guidance, and secure the right baler for your operation.

Recent Post

Types of Waste You Can Put in a Commercial Compactor

Business owners who are considering buying, leasing, or renting a compactor often ask…

Read More >The Pros and Cons of Using a Waste Broker

Commercial waste management decisions rarely stay simple for long. Costs shift, service needs…

Read More >