CALL NOW FOR A FREE QUOTE 866.760.8194

How to Troubleshoot Your Commercial Trash Compactor

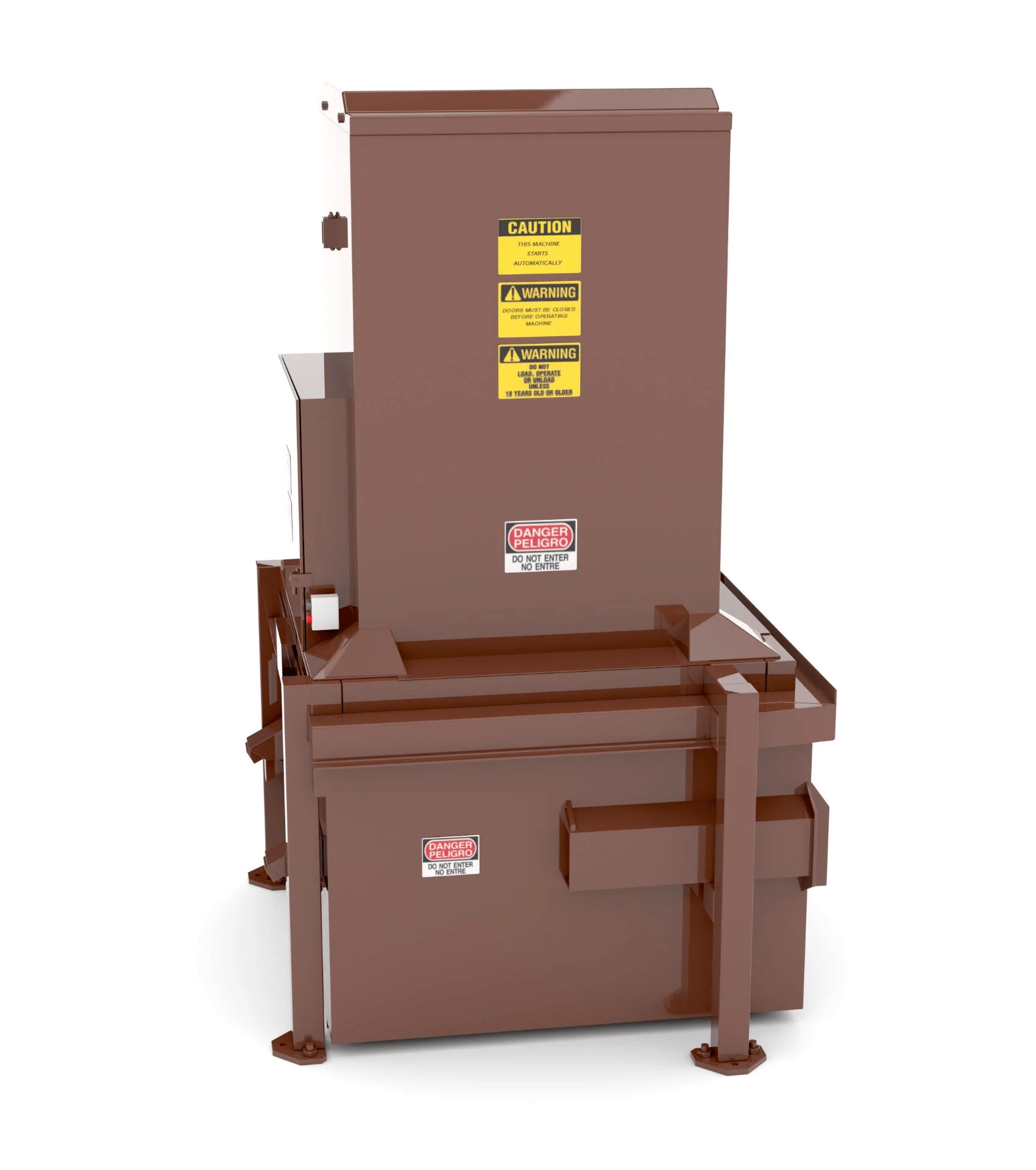

A commercial trash compactor supports smooth waste handling, yet even well-maintained units can develop issues. When a problem occurs, quick troubleshooting keeps operations on track and protects equipment. Let’s look at common reasons for a trash compactor not working and steps you can take to resolve them.

Safety Tips Before You Begin

Safety must come first. Follow these basics before inspecting or even attempting to fix a trash compactor:

- Disconnect power to prevent accidental activation.

- Keep hands and tools away from moving parts.

- Use proper lighting so every component is visible.

- Review your compactor’s manual to confirm safe access points.

- Never bypass safety switches or guards.

Common Reasons a Commercial Garbage Compactor Stops Working

Compactor problems often trace back to electrical faults, hydraulic issues, misaligned components, full containers, or worn parts. Here are some practical steps to try for the most common issues:

Trash Compactor Won’t Start

If the unit won’t turn on:

- Confirm it is plugged in and the breaker has not tripped.

- Check that the emergency stop button hasn’t been activated.

- Inspect interlock switches; a misaligned door latch or chute switch can block startup.

- Make sure the container is positioned correctly; it may not run if the bin isn’t seated.

- Look for loose wiring at the control panel.

If the machine remains nonresponsive, the issue may involve a failed start switch or a deeper electrical problem.

Trash Compactor Won’t Open

If you have difficulty getting the compactor to open:

- Confirm the cycle has completed and the ram is in the home position.

- Check the door interlock switch for misalignment or damage.

- Make sure packed waste isn’t pushing against the door.

- Clear any debris from the hinges or latch area.

- Verify the container is seated correctly and not binding the door.

If the door remains jammed after these checks, the cause may be a failed interlock switch, bent frame, hydraulic fault, or a warped door panel. Those issues require a technician.

Trash Compactor Motor Runs But the Ram Won’t Move

A running motor with no ram movement usually points to hydraulic issues. Start by:

- Checking hydraulic fluid levels; low fluid reduces pressure and stops motion.

- Confirming the hydraulic pump is operating.

- Looking for visible leaks around hoses or cylinders.

- Inspecting for clogged filters that restrict flow.

If the ram does not move after these checks, the unit may have a failed pump, damaged valve, or worn cylinder that requires a commercial compactor repair professional.

Trash Compactor Makes Loud or Unusual Noises

Grinding, knocking, or screeching sounds signal a mechanical problem. Consider the following steps:

- Look for debris caught in the ram path.

- Confirm bolts, guides, and panels are tightened.

- Inspect bearings and rollers for wear.

- Check hydraulic components for air in the system.

Persistent loud noise suggests a part is failing and should be assessed promptly to avoid further damage.

Trash Compactor Ram or Platen Gets Stuck Mid-Cycle

When the ram stops in the middle of a cycle:

- Confirm the machine still has power.

- Inspect for obstructions inside the chamber.

- Check hydraulic fluid levels and that hoses are connected.

- Clear any loose material on the rails.

- Verify the limit switches are not blocked or out of alignment.

If the ram remains stuck, there may be a valve or cylinder issue that requires professional attention.

Trash Compactor Cycles Slowly or Fails to Fully Compact

Slow cycling or incomplete compaction usually relates to reduced hydraulic pressure or resistance in the system. Try the following:

- Inspect hydraulic fluid for contamination; dirty oil affects performance.

- Check hydraulic filters and replace them if clogged.

- Look at the power supply; voltage drops limit motor strength.

- See if the chamber is overloaded; excess waste increases resistance and slows movement.

If performance does not improve, the hydraulic pump or motor may be wearing out, requiring garbage compactor repair.

When to Call a Repair Company

Basic checks help identify simple issues. Complex electrical faults, persistent hydraulic leaks, damaged parts, and control failures require expert repair. Attempting advanced repairs without training can increase downtime and create safety hazards. A qualified technician can safely diagnose underlying problems and repair your trash compactor quickly.

Contact Global Trash Solutions

If your trash compactor is not working, contact Global Trash Solutions for help. We provide expert support for commercial and industrial trash compactor repair, maintenance, and replacement. Our team can service commercial trash compactors from most major brands. To request assistance from our experienced repair technicians, call 866-760-8194 and schedule service.

Recent Post

Types of Waste You Can Put in a Commercial Compactor

Business owners who are considering buying, leasing, or renting a compactor often ask…

Read More >The Pros and Cons of Using a Waste Broker

Commercial waste management decisions rarely stay simple for long. Costs shift, service needs…

Read More >