CALL NOW FOR A FREE QUOTE 866.760.8194

Why Regular Commercial Garbage Compactor Preventative Maintenance Is Vital

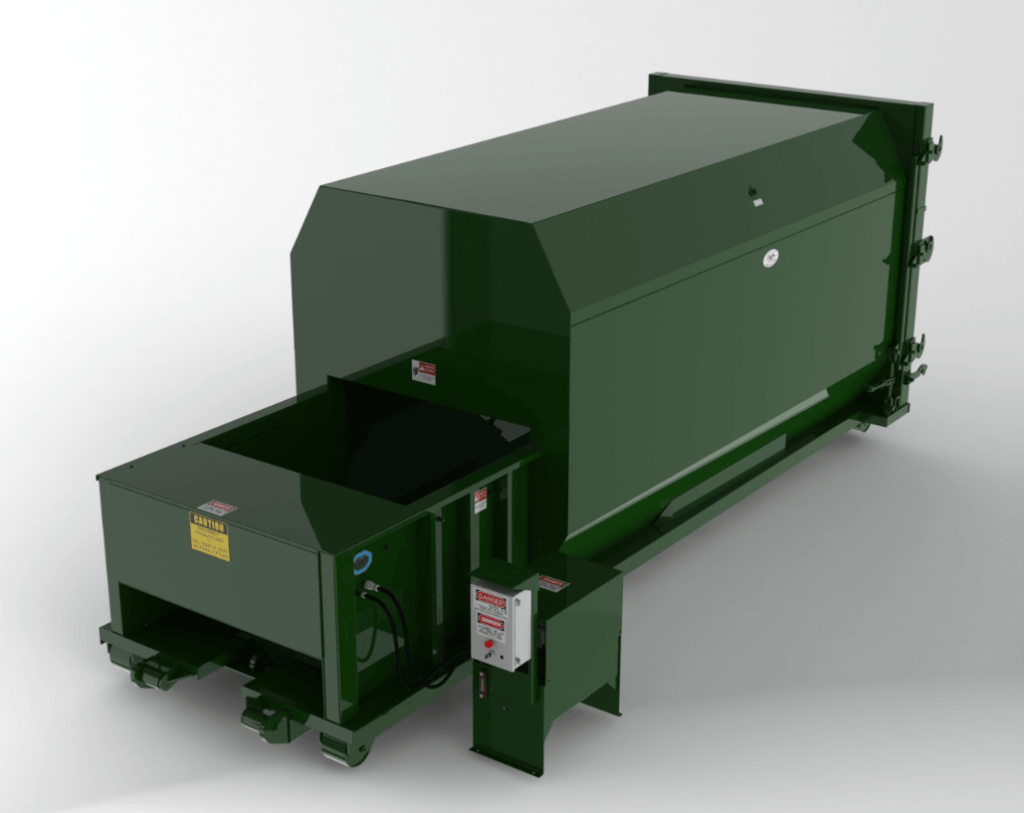

Investing in a commercial garbage compactor or a baler compactor machine can help reduce your waste management expenses. Simply purchasing the machine and having it installed at your business does not mean there are not things you need to do to keep equipment working correctly.

Heavy equipment like this requires regular preventative maintenance. The purpose of maintenance is to keep the compactor or baler running optimally. You need to ensure that your investment delivers the anticipated ROI (return on investment) by keeping the equipment working as it should for years to come.

Compactors and balers get used a lot and experience much general wear and usage daily. If you don’t perform regular maintenance on the machine, then the likelihood of breakdowns and other mechanical issues developing is increased.

All commercial trash compactors and balers come with a maintenance schedule. Take the time to review it to know what to do and when. Generally, you will want to perform the following maintenance tasks:

1. Run the clean cycle at the recommended intervals.

Several types of compactors and balers have a clean cycle on them. All you do is press the clean cycle button and the machine takes care of the rest. There might be some additional things you need to do, such as opening the compactor door and wiping down the compactor arm and assembly.

2. Inspect oil levels every few weeks.

Compactors and balers use hydraulics to provide the power needed to compact waste and recyclables. You want to make sure the fluid levels do not get low or run out.

3. Apply grease to door hinges, releases, and other such moving parts and components.

Refer to the owner’s manual to find out what parts of the compactor or baler machine need to be greased. Applying grease monthly helps protect these things from corrosion and ensures they do not seize up.

4. Inspect and change the oil filter as needed.

The oil used by the hydraulic system on the compactor or baler has an oil filter just like your car. It does need to be inspected at set intervals every two to three months and changed when it is dirty.

5. Maintain the exterior of the machine.

If you notice scratches in the painted exterior, make sure to touch them up right away. Otherwise, the exposed metal can rust. Fortunately, rust can be removed by sanding it until it is removed. Then apply a fresh coat of paint.

Additionally, make sure to replace any missing, worn, or faded warning labels, operational labels, etc.

6. Change the hydraulic oil at the recommended intervals.

Oil does not last forever and will need to be changed. The hydraulic system will have an oil tank with a drain plug in it. Simply remove the drain plug and drain the oil in an appropriate container for recycling. Then change the filter, if necessary, and refill the oil tank with new oil.

Performing maintenance is not that hard or difficult to do for most people. However, if you do not have a maintenance technician, you will want to speak to your commercial trash compactor and baler equipment provider. They may offer a maintenance program or can refer you to a qualified technician to take care of your maintenance needs.

To schedule maintenance or repairs on your commercial baler or compactor machine, or to learn about what type of trash compactor or baler would be best for your business and could help reduce your waste management expenses, please feel free to contact Global Trash Solutions at 866-760-8194 today!

We offer a free waste audit to help uncover different areas where you could save money!

Recent Post

Is Hiring a Waste Consultant Right for Your Business?

Managing waste and recycling needs poses a distinct hurdle for businesses focused on…

Read More >Understanding Scope 3 Emissions

Scope 3 emissions are an important component of a company’s total greenhouse gas…

Read More >