CALL NOW FOR A FREE QUOTE 866.760.8194

Which Commercial Baler Do You Need? Horizontal or Vertical?

If you are considering investing in a commercial baler for your business, the most important question you need to ask is if you really need one. If your business generates recyclable materials like cardboard, plastic, aluminum, Styrofoam, or others, then you could benefit from an industrial baler.

Why a Commercial Baler Is Beneficial for Your Business

Whether you choose a horizontal or vertical baler, balers, in general, play an important role in helping you recycle a wide range of materials by compacting them down into easy-to-manage bales, or bundles. Other benefits balers can provide businesses include:

- Recyclables are compressed into bundles which make them easier to store and move.

- Keeps work areas free from trash, debris, and other potential hazards.

- Helps do your part to reduce your carbon footprint and keep materials out of landfills.

- Provides a means for your business to earn new revenues by selling recyclables to various buyers.

Which Industrial Baler Is Best for My Business?

Baler machines come in two different configurations: horizontal and vertical. One configuration is not superior to the other. Rather, each configuration operates slightly differently, depending on:

- The types of materials you are baling.

- The volume of baling.

- How regularly you need to bale materials.

- How many employees you have to perform baling.

- The amount of space available at your business for the equipment.

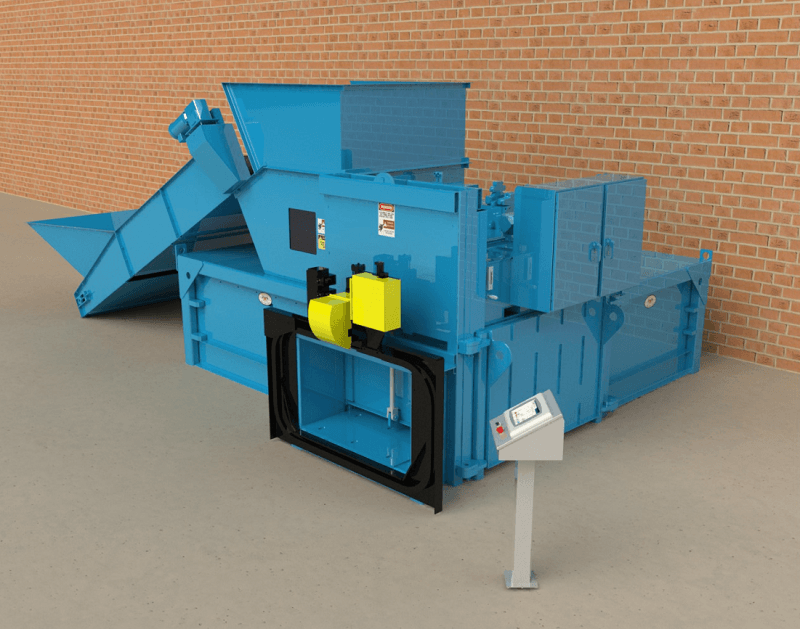

Why Choose a Horizontal Commercial Baler?

Horizontal balers are designed to work with specific materials, depending on what waste your business generates. There are three different general configurations of horizontal balers:

- Closed End Balers

- Auto Tie Balers

- Wide Mouth Balers

The types of functions one can perform is directly related to the configuration of horizontal baler selected. Some of the benefits your business could gain with a horizontal baler include:

- Horizontal balers can make all different sizes of balers, even huge “mill-size” bales.

- Horizontal balers allow you to process a larger volume of materials.

- Horizontal balers can help you automate recycling and baling processes with auto feed and auto tie features.

- Horizontal balers are faster since there is often a separate hopper and compacting area.

Horizontal balers are well-suited for factories, manufacturing, recycling centers, and other large-scale operations. They are also the perfect solution when they are shared by multiple businesses like all the businesses at a shopping center or mall.

Why Choose a Vertical Industrial Baler?

Vertical balers are designed to be manually loaded and fed recyclables. Some of the advantages of vertical balers include:

- There are several different size configurations of vertical balers available.

- A single employee can easily load and operate a vertical baler.

- Vertical baling machines have a smaller footprint, so they take up less space.

- Vertical balers are perfect for small businesses.

- Vertical balers can process plastic, cardboard, paper, aluminum, rags, and more.

- Vertical balers are available with different electrical power configurations.

Vertical balers are a good choice for motels, hotels, restaurants, fast-food chains, cruise ships, small medical facilities, hospitals, retail stores, and grocery stores.

Choosing a horizontal or vertical baler is the first step to start saving money on your waste management costs. By selling your recyclables, you can easily recover the initial investment costs into a baler machine.

To discover other ways to save money on your waste management costs, help selecting a horizontal or vertical baler, or to request a free waste evaluation, please feel free to contact Global Trash Solutions at 866-760-8194 today!

Recent Post

Is Hiring a Waste Consultant Right for Your Business?

Managing waste and recycling needs poses a distinct hurdle for businesses focused on…

Read More >Understanding Scope 3 Emissions

Scope 3 emissions are an important component of a company’s total greenhouse gas…

Read More >