CALL NOW FOR A FREE QUOTE 866.760.8194

Using Baler Equipment 101: A Guide to Commercial Balers

For businesses of all sizes, investing in the right baler equipment can result in generating new revenues and helping the environment. You would be surprised to learn that you could essentially take your cardboard, Styrofoam, plastic, paper, and other such materials you normally toss in the trash and turn it into cold hard cash.

Using an industrial baler helps compact down all these things and keeps them out of your dumpster and normal waste stream. Instead of ending up in a landfill, you sell your baled recyclables to buyers, which range from local recycling centers to manufacturing operations.

Whether you are looking for ways to cut your waste management costs or new ways to make money for your business, you cannot go wrong with a commercial baler. Baler machines offer many benefits and considerations to ensure you select the best baler for your business.

A Commercial Baler Pays for Itself

While you do need to make an initial investment upfront for your baler equipment, the long-term payoff is knowing your investment will pay for itself. How long that takes depends on the volume and types of materials being recycled.

This is why it is important to think about your output volume before investing in a machine. If you only have a small volume of materials to bale, then it makes more sense to invest in a smaller machine than a huge horizontal baler.

An Industrial Baler Will Take Up Space

One of the most important considerations is how much space you have available for your commercial baler. You have to ensure your facility, restaurant, fast-food chain, hotel, grocery store, retail store, or other business has sufficient room to place the machine.

The baler should not block walkways or other work areas, nor should it create new workplace safety hazards. Rather, the machine should be installed in an easily accessible location without hindering current work functions.

Some businesses place their baler machine next to the location where they are keeping their recyclable materials. This way, they can more efficiently bale the materials once they have a sufficient amount.

How Does a Cardboard Baler Work?

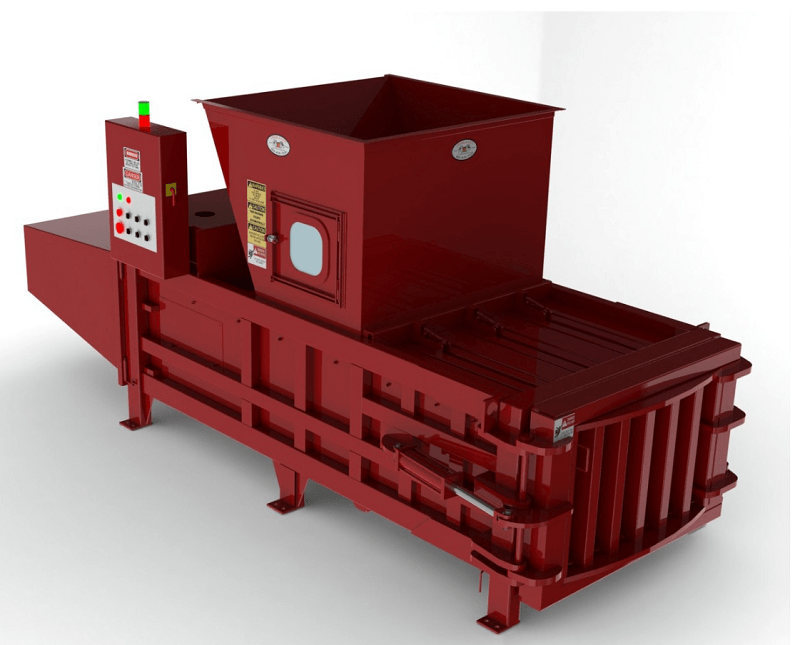

Vertical and horizontal cardboard balers function much the same way, although the operating procedure might differ slightly based on the type of model used. They all work by using a hydraulic pressing plate to compress cardboard by up to 90% in volume.

- A batch of cardboard waste is loaded into the compression chamber.

- The chamber is closed with a safety gate or apparatus to protect the operator and others from moving parts.

- The compression cycle is started by the machine operator, which may use a push button, a floor pedal, or a touchscreen.

- A hydraulic ram will press the compression plate home to fully compress each load of new cardboard material.

- When the machine is full of compressed cardboard, an indicator light or alert will let the operator know it is time to strap the bale and remove it from the machine.

- Bales are wrapped with wire or twine, and then ejected from the machine mechanically or removed manually with a forklift.

What Safety Features Are on the Commercial Baler?

Safety features are important for you and your employees. When operating a baler, safety needs to be the top priority. If they are not operated correctly or materials are put into the machine that it was not designed to compact, it can increase risks of accidents and injuries.

Before allowing any of your employees to operate and use a baler, you need to make sure they have been trained correctly and understand all safety requirements. It is also a good idea to post reminders near the baler, using signs and posters that illustrate safe operating procedures.

Selecting Baler Equipment

For smaller operations, a vertical baler is a better choice because it has the smallest footprint, compared to horizontal balers. For large-scale operations with plenty of room, a horizontal baler is a better choice, especially if you are looking to automate certain baling processes.

If you are not sure which baler would be best for your business, we recommend requesting our free waste evaluation. During this evaluation, our waste consultants review your current waste management processes and offer advice on how you can save money, including which baler would be best for your business.

Investing in a baler can help your business earn more money while you are also reducing your carbon footprint. You could even discover other ways to save money on your waste management costs with our free waste consultation.

To request your free waste consultation, learn more about baler equipment, or get help selecting the best baler for your business, please feel free to contact Global Trash Solutions at 866-760-8194 today!

Recent Post

Is Hiring a Waste Consultant Right for Your Business?

Managing waste and recycling needs poses a distinct hurdle for businesses focused on…

Read More >Understanding Scope 3 Emissions

Scope 3 emissions are an important component of a company’s total greenhouse gas…

Read More >